Dry Ice Cleaning in Round Rock – A Eco-Safe Method for Manufacturing Cleaning

Dry Ice Cleaning in Round Rock – A Eco-Safe Method for Manufacturing Cleaning

Blog Article

Discover the Reasons Your Cars And Truck Will Certainly Take Advantage Of Automotive Dry Ice Blasting Strategies

Automotive dry ice blasting strategies represent a considerable innovation in automobile upkeep, providing an array of advantages that extend beyond standard cleansing approaches. As the automotive market proceeds to accept sustainable techniques, comprehending the complete range of these advantages can fundamentally alter exactly how you care for your auto.

Eco Pleasant Cleaning

Among one of the most noteworthy benefits of dry ice blasting is its minimal environmental effect. As the solidified carbon dioxide sublimates upon contact with surface areas, it changes straight from solid to gas, leaving no secondary waste. This particular not just preserves water yet additionally removes the demand for chemical additives that can be dangerous to both the atmosphere and human health and wellness.

Additionally, completely dry ice blasting is secure for different automobile components, consisting of sensitive electrical systems and elaborate engine components. This technique enhances the overall tidiness of cars while aligning with eco-conscious methods, interesting both auto experts and ecologically conscious customers (ice blasting). As the sector fads towards sustainability, solidified carbon dioxide blowing up attracts attention as a useful and reliable solution in auto upkeep

Efficient Contaminant Elimination

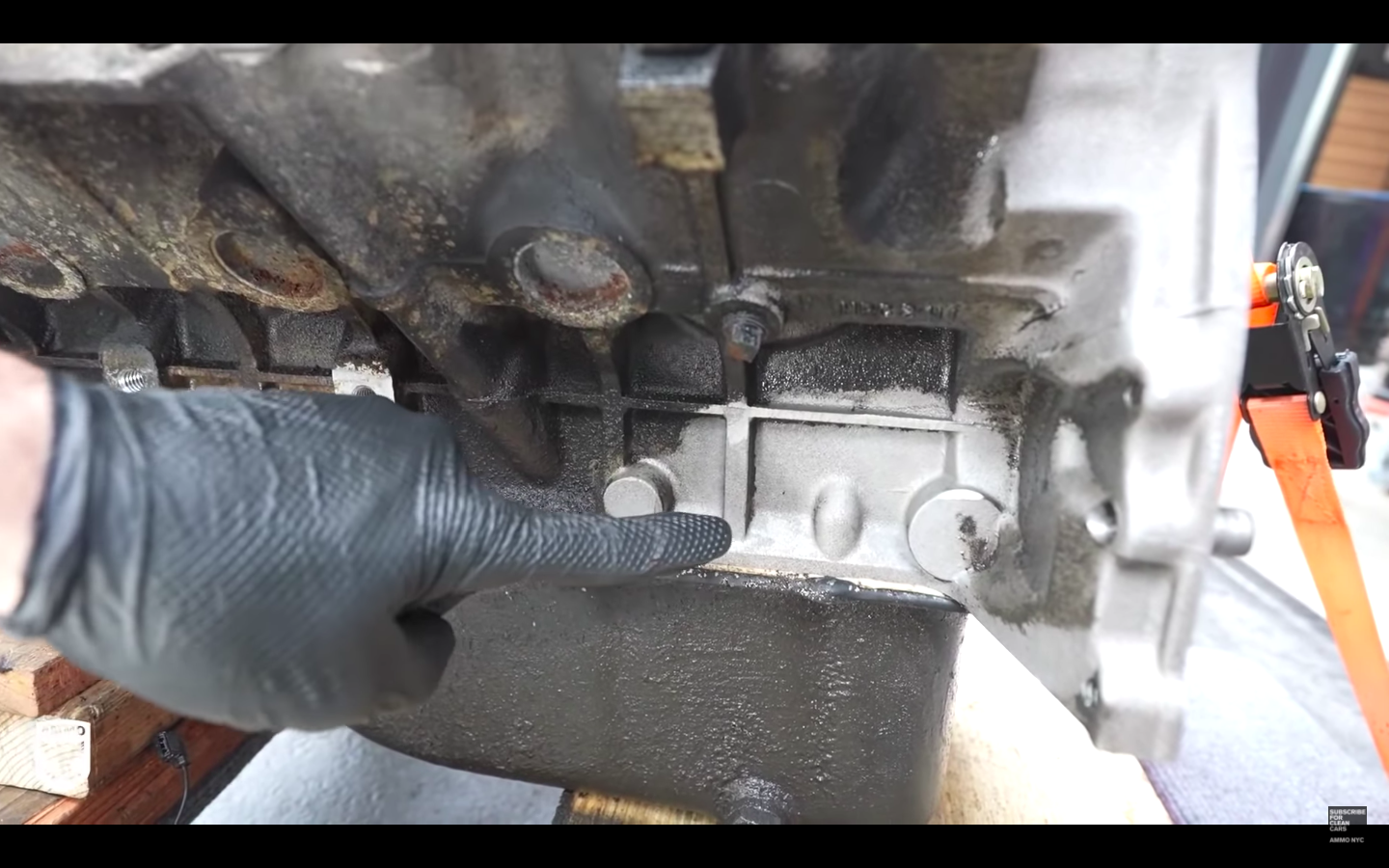

With a powerful mix of kinetic energy and thermal shock, completely dry ice blowing up excels in the efficient removal of numerous impurities from automotive surfaces. This ingenious cleaning approach makes use of strong carbon dioxide pellets that, upon impact, sublimate and develop a rapid temperature level decrease. This procedure successfully dislodges contaminants such as grease, dirt, carbon, and oil down payments without the demand for harmful chemicals.

The kinetic power created during the blowing up procedure pushes the solidified carbon dioxide pellets at broadband, allowing them to pass through the layers of grime and debris on engine elements, undercarriages, and various other hard-to-reach areas. As the pellets hit the surface area, they increase and cause the contaminants to split and drop away, resulting in a detailed and efficient cleaning.

In addition, solidified carbon dioxide blasting is particularly reliable for getting rid of stubborn deposits that conventional cleansing techniques struggle to get rid of. This includes baked-on materials that collect with time, which can impede performance and result in expensive repairs - dry ice cleaning. By using this advanced technique, automobile proprietors can guarantee their cars stay in ideal problem, improving both longevity and efficiency

Non-Damaging to Surface Areas

Dry Ice blowing up not only masters impurity elimination yet additionally ensures that surface areas continue to be intact during the cleaning process. This cutting-edge strategy uses solid carbon dioxide pellets that sublimate upon impact, producing an effective yet mild cleansing approach. Unlike conventional abrasive cleaning approaches, which can mar or scratch surface areas, dry read the article ice blasting operates at a reduced temperature and depends on kinetic power to remove dirt, crud, and other contaminants without endangering the honesty of view the underlying material.

The non-abrasive nature of solidified carbon dioxide blowing up makes it especially advantageous for delicate automotive components, such as electric systems, delicate paint coatings, and complex engine components. As the dry ice pellets struck the surface, they expand and evaporate, leaving no deposit behind and reducing the risk of damages. This characteristic not only preserves the aesthetic appeal of lorries yet additionally extends the life-span of important parts.

Time and Labor Efficiency

The performance of time and labor is considerably enhanced with the use of completely dry ice blowing up in auto cleansing procedures. This cutting-edge technique speeds up surface area preparation and cleaning, drastically reducing the moment required to accomplish optimum results. Standard cleansing methods commonly include considerable manual work, which can be both labor-intensive and time-consuming. On the other hand, solidified carbon dioxide blowing up automates much of the cleansing procedure, making it possible for professionals to concentrate on other necessary tasks.

In addition, completely dry ice blasting removes the need for disassembly of components, as it can properly clean up complex areas without the danger of harmful parts. This not only shortens the overall cleansing time but additionally reduces labor costs connected with reassembly and additional labor hours. The solidified carbon dioxide pellets sublimate on contact, leaving no residue behind, which additionally improves the cleansing process.

Additionally, the capacity to perform solidified carbon dioxide blasting in situ suggests that lorries can continue to be operational during cleaning, lowering downtime and boosting productivity. As a result, auto specialists can serve a lot more customers within an offered duration, inevitably causing boosted operations and performance across the board. Embracing completely dry ice blasting is a tactical relocation for any kind of vehicle solution intending for superior time and labor efficiency.

Economical Upkeep Remedy

An economical upkeep remedy is important for automotive provider aiming to maximize their productivity while supplying high-grade outcomes. Automotive solidified carbon dioxide blowing up methods supply a distinct approach to automobile cleansing and upkeep, decreasing prices connected with standard cleansing approaches. This ingenious this hyperlink strategy utilizes solidified carbon dioxide pellets to eliminate contaminants without the need for severe chemicals or excessive water, leading to considerable financial savings on both products and disposal costs.

In addition, completely dry ice blowing up minimizes labor time, enabling professionals to concentrate on additional services instead of considerable cleansing processes. This effectiveness translates right into quicker turnaround times for consumers, boosting general fulfillment and fostering repeat business. The eco-friendly nature of dry ice additionally positions provider positively in an eco mindful market, attracting a larger clientele.

Moreover, since solidified carbon dioxide vaporizes upon impact, there is no need for extensive drying time, reducing downtime for vehicles and making best use of workshop performance. By adopting dry ice blasting, automobile provider can simplify their procedures, boost service offerings, and inevitably boost their profits. In summary, completely dry ice blasting is not just an upkeep method; it is a strategic financial investment that pays returns in performance and cost-effectiveness.

Verdict

In summary, auto completely dry ice blasting techniques offer a wide range of advantages for lorry upkeep. By adopting completely dry ice blasting, car maintenance becomes much more sustainable and effective, eventually boosting the long life and performance of automobiles.

Automotive dry ice blowing up techniques stand for a considerable improvement in car upkeep, providing a range of advantages that expand past standard cleaning approaches.In the realm of vehicle maintenance, ecologically pleasant cleaning techniques have actually obtained considerable grip, with dry ice blowing up emerging as a leading technique.The performance of time and labor is significantly improved through the use of dry ice blowing up in vehicle cleaning procedures. Automotive completely dry ice blasting techniques use a distinct method to lorry cleaning and maintenance, decreasing expenses linked with conventional cleansing methods.In addition, because dry ice vaporizes upon impact, there is no demand for comprehensive drying time, lowering downtime for automobiles and optimizing workshop efficiency.

Report this page